Understanding Butterfly Valve Seat Types: A Comprehensive Overview

Butterfly valves are essential components in fluid control systems, widely used across industries like water treatment, chemical processing, and HVAC. The seat of a butterfly valve plays a pivotal role in its functionality. It ensures a proper seal between the valve disc and the valve body, preventing leaks and ensuring optimal performance. But did you know there are various types of valve seats to consider depending on the application? Let’s explore them in more detail.

1. Resilient Seat

The resilient seat is the most common type of valve seat. Made from materials like rubber or elastomers, it offers excellent sealing performance, especially in low-pressure systems. Resilient seats are cost-effective and provide a good balance of durability and flexibility. They are ideal for applications where a tight shutoff is required without the need for excessive wear resistance.

2. Metal Seat

In more demanding environments, a metal seat may be the better option. Metal seats are typically made from alloys like stainless steel, and they offer superior resistance to high temperatures, pressure, and abrasive materials. These seats are ideal for industries such as oil and gas, where robust performance in extreme conditions is critical. They are less prone to wear and tear compared to resilient seats, but they might not offer as tight a seal at low pressures.

3. Combination Seat

A combination seat merges the benefits of both resilient and metal seats. Typically, the valve body is equipped with a metal insert, and the sealing material on the valve disc is made from a resilient material like rubber. This type of seat provides a longer lifespan and can handle a broader range of operating conditions. It’s commonly used in industries where versatility and long-term performance are essential.

4. High-Performance Seat

High-performance butterfly valves feature seats designed to perform under demanding circumstances, such as high pressures and fluctuating temperatures. These seats are usually made of advanced materials like PTFE or a metal-clad elastomer to ensure both durability and excellent sealing performance. High-performance seats are often found in critical applications where failure is not an option.

In conclusion, choosing the right butterfly valve seat type is essential for ensuring the longevity and efficiency of your valve. Each seat type offers unique benefits suited to specific needs, so understanding the demands of your system will guide you toward the ideal choice.

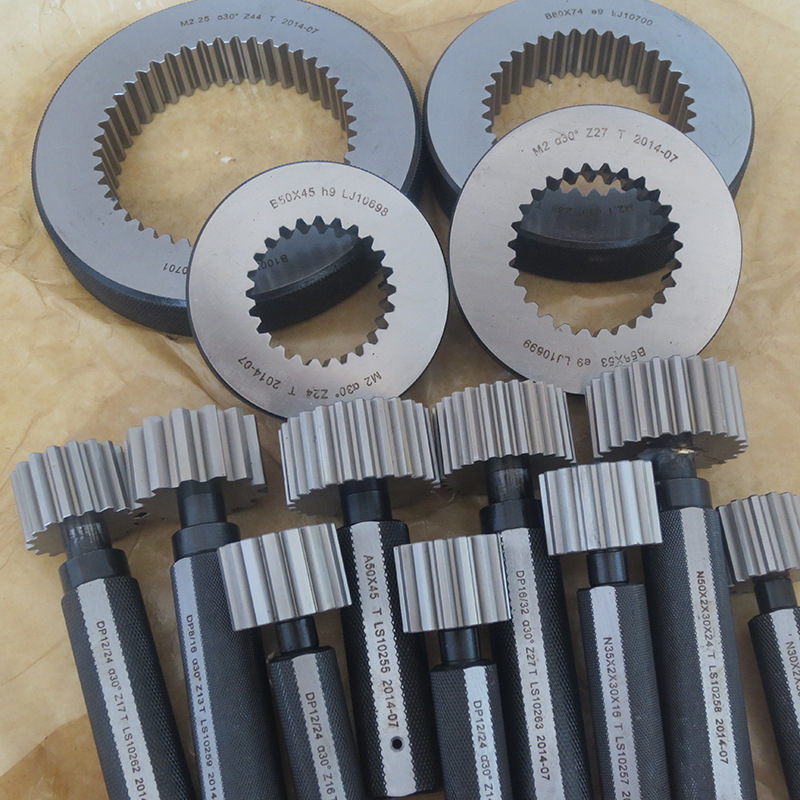

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.