When every second counts in your process plant, reliability isn’t a luxury—it’s a mandate. The welded globe valve is engineered to deliver both control and confidence, even under the toughest conditions. By combining a robust welded bonnet with a butt-weld end connection, this valve forms a single, continuous pressure boundary that resists leaks, corrosion, and thermal shock better than many bolted designs.

From the moment pipes are mated to the last stroke of the actuator, the welded globe valve stands apart. The absence of gaskets at critical joints means fewer potential leak points, less maintenance, and simpler commissioning. The compact, high-integrity body houses a precise throttling mechanism: the globe-shaped disc meets a smooth seat for predictable, fine control of flow across the fully open to fully closed range. This makes it ideal for throttling services, where stable control and tight shut-off are paramount.

Our welded globe valves are available in a wide range of materials—carbon, stainless, and alloy steels, with specialized coatings for corrosive or high-temperature service. They’re designed for elevated pressures and temperatures, as well as demanding media like steam, hot water, hydrocarbons, and aggressive chemicals. End connections are engineered to welding standards, ensuring a clean, vibration-free installation that integrates seamlessly with piping systems in refineries, power plants, chemical plants, and offshore platforms.

Customers report lower total cost of ownership: longer service life, fewer commissioning iterations, and reduced risk of leaks across the valve’s life cycle. The welded construction also translates to easier, faster maintenance in the field: when a station needs service, the valve can be handled without compromising the integrity of surrounding joints, and spare parts are readily available through established supply chains.

If you’re designing for reliability, choose a valve that merges precision with endurance. Our welded globe valves combine rigorous testing, strict quality control, and customization options—from trim shapes and seat alloys to coatings and actuators—so you get exactly what your system requires. In a world that never slows down, let your pipeline know that control, safety, and efficiency can be welded into every connection.

Installation guidance is part of the package: welding procedures, heat-treatment recommendations, and field-service support to minimize downtime. The welded connection remains robust through seismic events and thermal cycling, providing a reliable backbone for critical lines. For projects with aggressive schedules, we maintain regional inventories and flexible manufacturing to meet tight lead times.

Choosing a welded globe valve is more than a component choice; it’s a commitment to safety, uptime, and operating efficiency. If you’re building the next generation of pipelines—refineries, power plants, or chemical plants—contact us for datasheets, performance data, and a tailored quote.

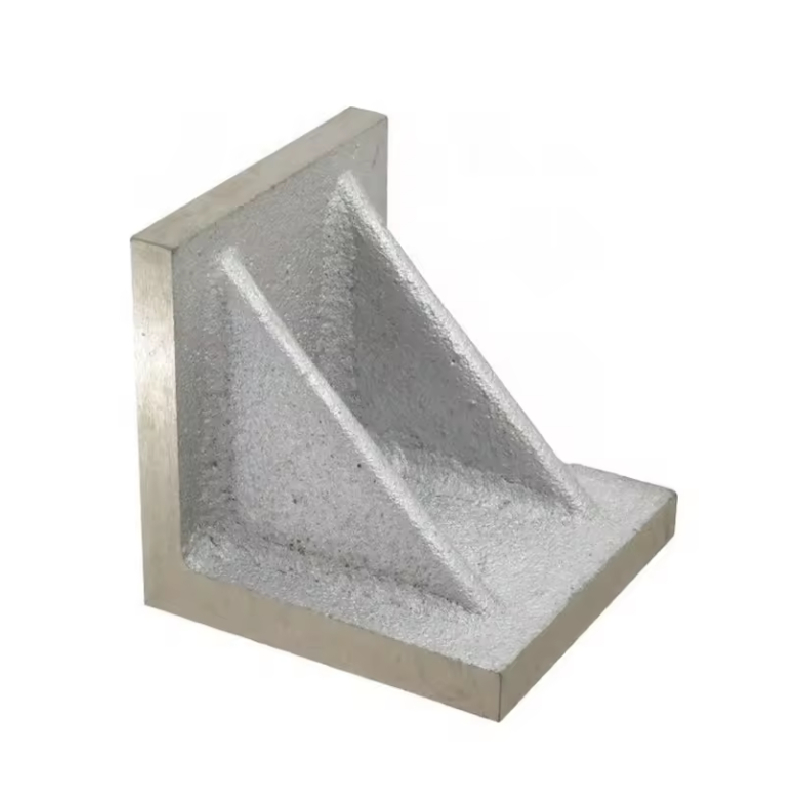

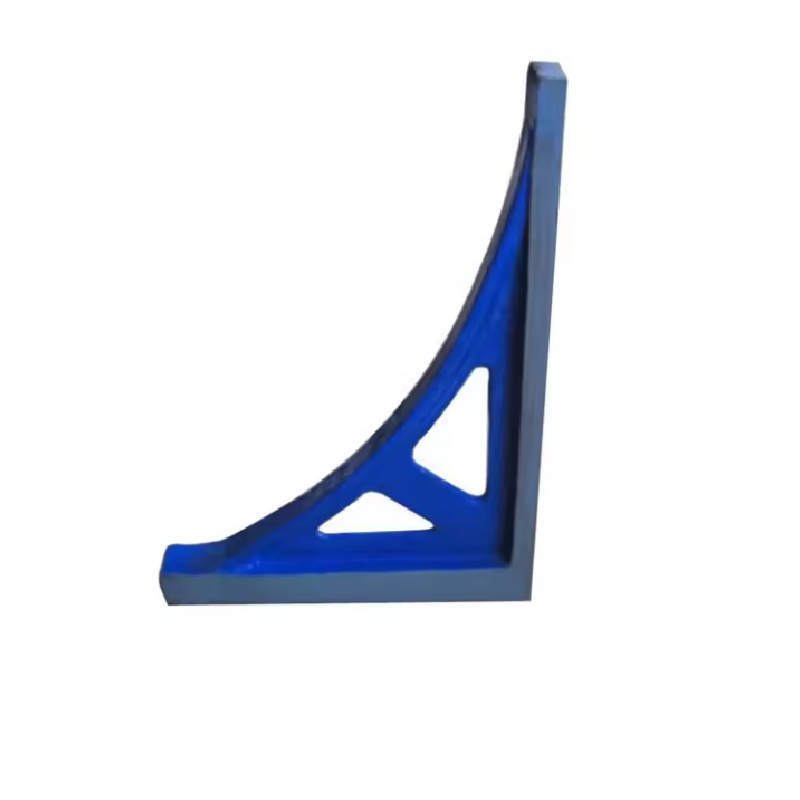

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.