On the industrial stage, valves are the quiet workhorses that keep temperatures steady, pressures safe, and processes predictable. Among globe valves, the balanced globe valve stands out for throttling under challenging differential pressure. It delivers precision with less mechanical effort, making demanding control tasks reliable.

The secret is its balanced design: a balanced plug and a piston chamber neutralize most hydraulic force on the stem. When pressure pushes against the valve, opposing forces cancel part of the load that a traditional globe valve would bear. The result is reduced actuator torque, smoother motion, and longer life for seats, stems, and seals. In practice, you gain faster response, finer throttling, and less wear over time.

Operators value its consistent shut-off and stable flow. With accurate seating and tight shutoff, it minimizes leakage and cavitation risk while maintaining process integrity in high-temperature and high-pressure service. The valve can be customized with anti-cavitation or noise-reducing trims to suit fluid and duty cycles.

Reliability comes from robust materials and engineering. Bodies in stainless steel, carbon steel, and alloys resist corrosive media and thermal cycling; seats and seals are chosen for chemical compatibility; stems resist galling. End connections range from standard flanged to butt-weld, with fire-safe options and QA aligned to industry standards.

For operators, the payoff is straightforward: lower total cost of ownership through reduced energy use, fewer maintenance cycles, and longer service intervals. In chemical plants, power stations, water treatment facilities, and oilfields, the balanced globe valve translates precision into efficiency and safety into routine control.

If you’re evaluating throttling solutions, consider how a balanced globe valve can fit your differential pressure, medium, and temperature. We can tailor a valve to your plant’s heartbeat, delivering reliable control and long-term value.

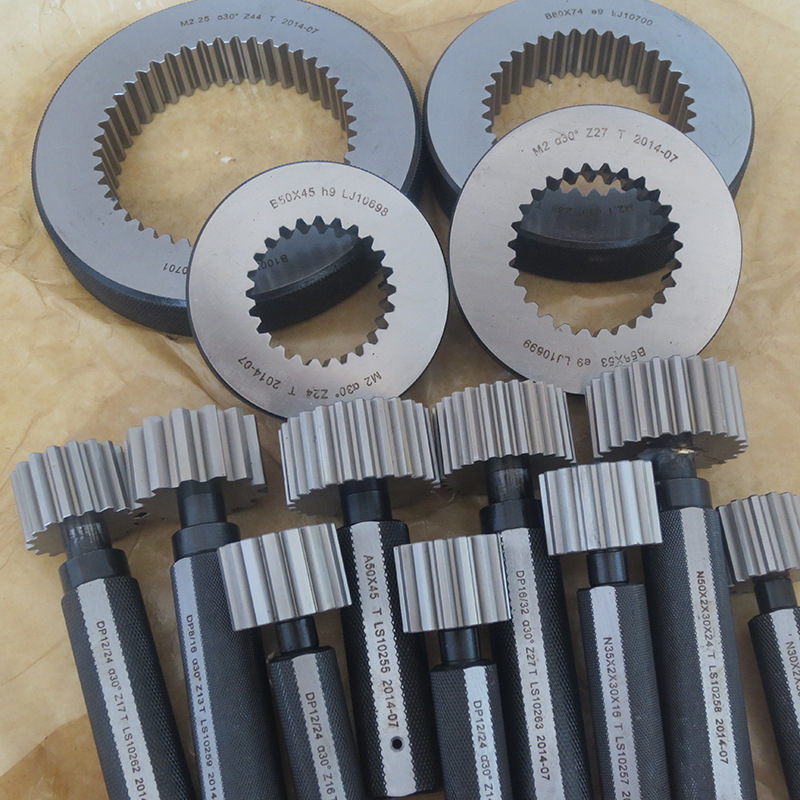

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.