In the moment a butterfly valve opens, a quiet promise travels through the pipeline: control, efficiency, and reliability. It is not merely a mechanical action; it is a deliberate choice to streamline a process, to reduce energy use, and to safeguard product quality. When the disk rotates away from the seat, it does so with a light touch and a firm result—an elegant transition from restraint to flow.

A butterfly valve open signifies design that favors speed without sacrifice. Its disk pivots on a stem, turning a full 90 degrees to reveal a clear passage. In open position, the valve offers minimal obstruction, allowing high flow with low pressure drop. This means less energy required to push liquids or gases through the system, and less wear on pumps and compressors over time. Yet the magic lies not just in speed, but in precision: the same valve that opens quickly can be coaxed to close with exacting sealing, preventing leaks and protecting downstream processes.

Materials and engineering make the difference when the valve is open—and when it is closed. The body can be light yet sturdy, the seat resilient for a long service life, and the disc edge crafted for smooth operation under challenging conditions. From food-grade elastomers to chemically resistant coatings, from compact compact drives to powerful actuators, every choice is about ensuring that the moment of open is predictable, repeatable, and safe. In open position, a well-made butterfly valve minimizes turbulence and noise, contributing to a calmer, cleaner, more efficient plant floor.

Industries trust this open moment because it aligns with practical goals: faster commissioning, easier maintenance, and scalable control. In water treatment, it means more precise dosing and healthier infrastructure. In HVAC, it translates to comfortable environments with lower energy bills. In chemical processing and petrochemicals, it provides reliable flow control even under demanding temperatures and corrosive media. And in food and beverage, it guards hygiene while delivering consistent throughput. The result is a small component with a large impact—the difference between a system that suffocates under resistance and one that breathes freely at full open.

Choosing the right butterfly valve means prioritizing quality, compatibility, and service. It means warranties you can trust, global standards, and partners who listen as closely as they design. When you hear that familiar, confident click of the lever or actuator reaching open, you’re not just hearing a mechanism; you’re hearing a decision to perform better tomorrow. Butterfly valve open. A simple act, a powerful outcome.

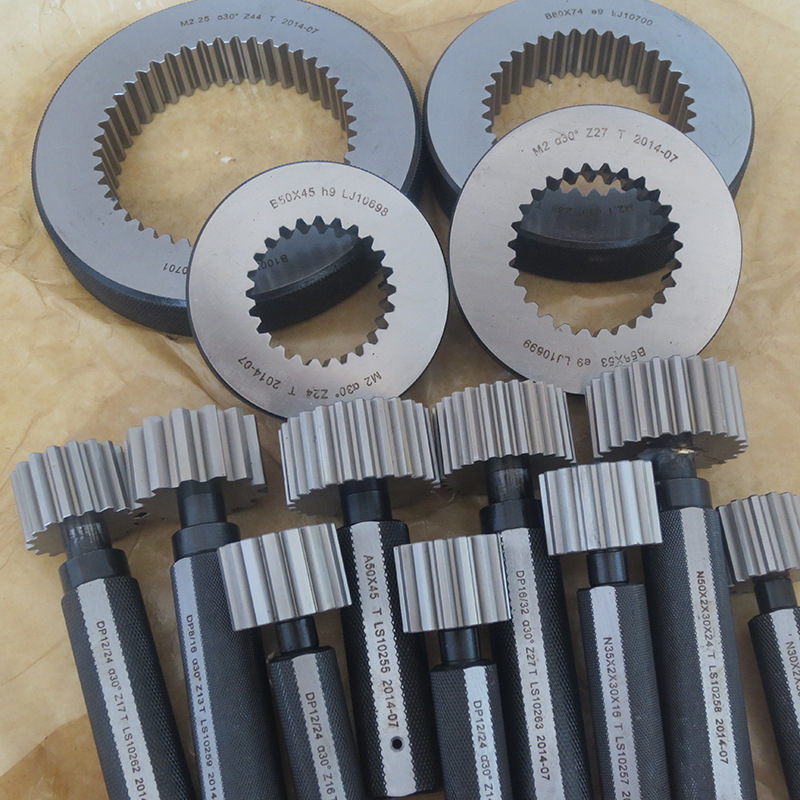

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.