In the daily chorus of modern industry, the control valve plays the lead singer’s role without stealing the spotlight. Small, dependable, and precise, it shapes everything from the heat of a chemical reactor to the chill of a cooling loop. When a plant runs at its best, a control valve is quietly doing its job in the background, ensuring performance that can be measured, repeated, and trusted.

At its core, a control valve is a clever actuator and a faithful partner to the control loop. A signal from the process controller asks for more or less flow. The actuator moves the valve, the valve throttles the stream, and sensors confirm the effect. The result is a stable process: controlled temperature, steady pressure, precise flow. The magic happens in the details—the valve’s seating, materials, and the responsiveness of the actuator.

Why does this matter? Because precise control translates into energy savings, longer equipment life, safer operations, and higher product quality. Even small improvements in modulation can trim utilities use, reduce waste, and minimize emissions. In batch and continuous processes alike, reliable valves prevent oscillations, limit risk, and keep you compliant with tough process standards.

Choosing a valve means weighing speed, range, and accuracy. Look for: high Cv accessibility across the range, tight shut-off, robust materials suited to the media, anti-cavitation features, and a reliable positioner. Consider smart options: valves with built-in diagnostics, remote monitoring, and compatibility with your control system (DCS, PLC, or SCADA). Predictive maintenance data can turn surprise failures into planned outages.

Industries across chemical, oil and gas, power generation, water treatment, and food and beverage trust control valves to perform from the first start-up to the last shut-down. In harsh environments or critical service, the right valve design—plus proper installation and routine testing—delivers predictable results and lower total cost of ownership.

At the heart of every reliable plant is a thinking partnership. A valve is not just a component; it is built into your process philosophy. Choose a partner who offers engineering support, customized solutions, and service that travels with you—from commissioning to upgrade and beyond.

Invest in a control valve as an investment in process confidence. When you demand accuracy, efficiency, and peace of mind, you invite performance that speaks for itself—through quality, consistency, and measurable gains. Whether you’re upgrading a legacy plant or designing a new facility, a well-chosen control valve aligns technology with intention. It is where engineering meets reliability, and where your teams can breathe easier knowing the process behaves as designed.

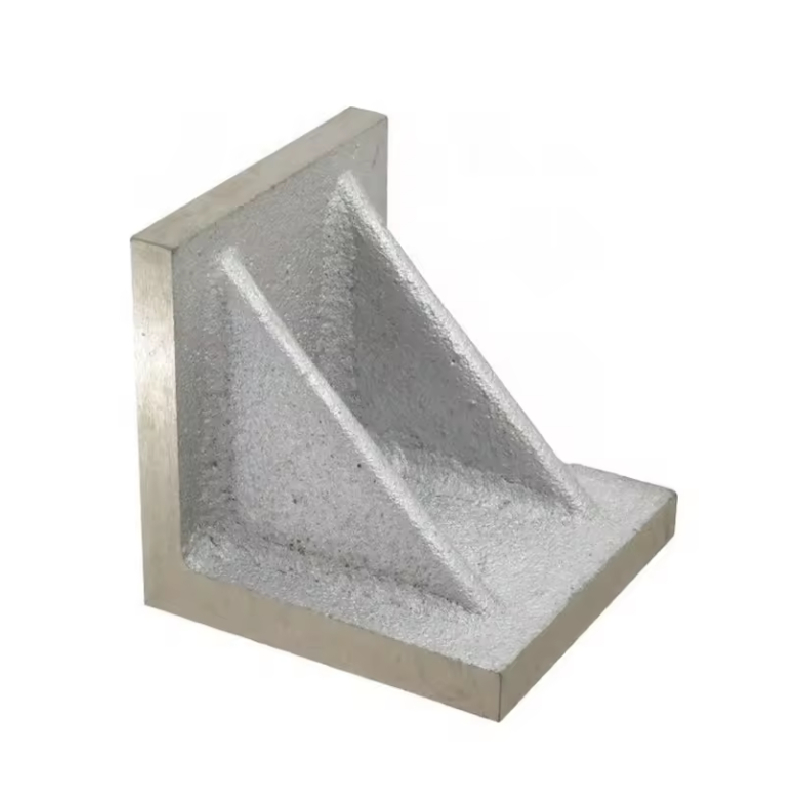

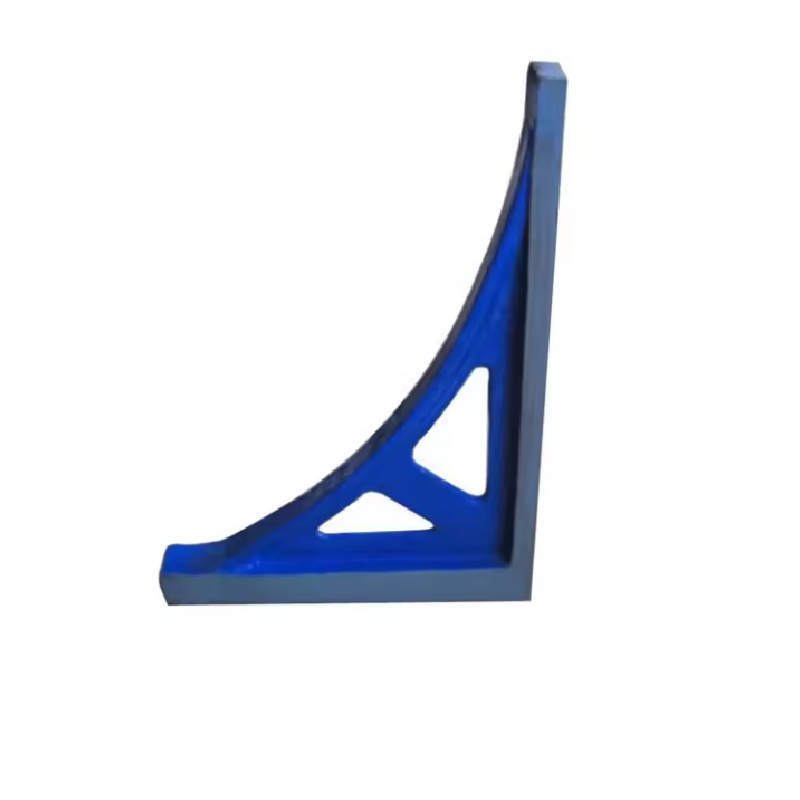

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.