In every fluid system, a tiny gate keeps big problems at bay: a one-way check valve. It opens to let your liquid glide forward, then closes to stop backflow with a quiet, decisive snap. It’s the unsung guardian that protects pumps, preserves product purity, and preserves your integrity when systems face pressure surges, sudden reversals, or cross-contamination.

Imagine a hospital’s water line, a chemical process loop, or an irrigation main. A stray backflow can contaminate an entire line, crash a filtration stage, or send expensive chemicals coursing toward unexpected destinations. The one-way check valve is the immediate line of defense—designed to respond faster than human intervention, preventing reverse flow even under sudden pressure spikes. It is simple in principle, powerful in practice, and remarkably forgiving in everyday operation.

What makes a quality check valve stand out? It starts with a robust design. Depending on your needs, you may choose a swing, tilting-disc, or ball check valve, each tuned for rapid closure and reliable seating. Materials matter: stainless steel for corrosive environments, bronze for reliability in water systems, or durable plastics for low-weight, low-cost installations. The best valves feature a soft seat or resilient elastomer that creates a tight seal without sticking, even after long idle periods. And with wafer, lug, or flanged configurations, installation fits snugly into your piping, minimizing installation time and space requirements while maximizing flow efficiency.

The benefits extend beyond protection. A properly selected check valve minimizes energy losses by reducing backflow-induced pressure fluctuations, saves maintenance by guarding pumps against back-driven surges, and lowers the risk of system-wide shutdowns. In industries ranging from water treatment and beverage production to HVAC and automotive cooling, it’s a small device with outsized impact. Cleaner product, quieter operation, longer equipment life, and compliant processes all ride on the reliability of a dependable check valve.

Choosing the right valve is about knowing your operating window: forward flow rate, maximum backpressure, temperature, and chemical compatibility. Consider installation orientation, anticipated debris, and maintenance access. Look for features like a reliable seat design, robust stem, and corrosion-resistant fasteners. With these in hand, you’ll gain a system that breathes easy—one that acts intelligently, quietly, and consistently.

Invest in a one-way check valve and empower every stage of your process to stay forward-focused. It’s not merely a component; it’s peace of mind wrapped in a small, sturdy package that never stops protecting what matters most.

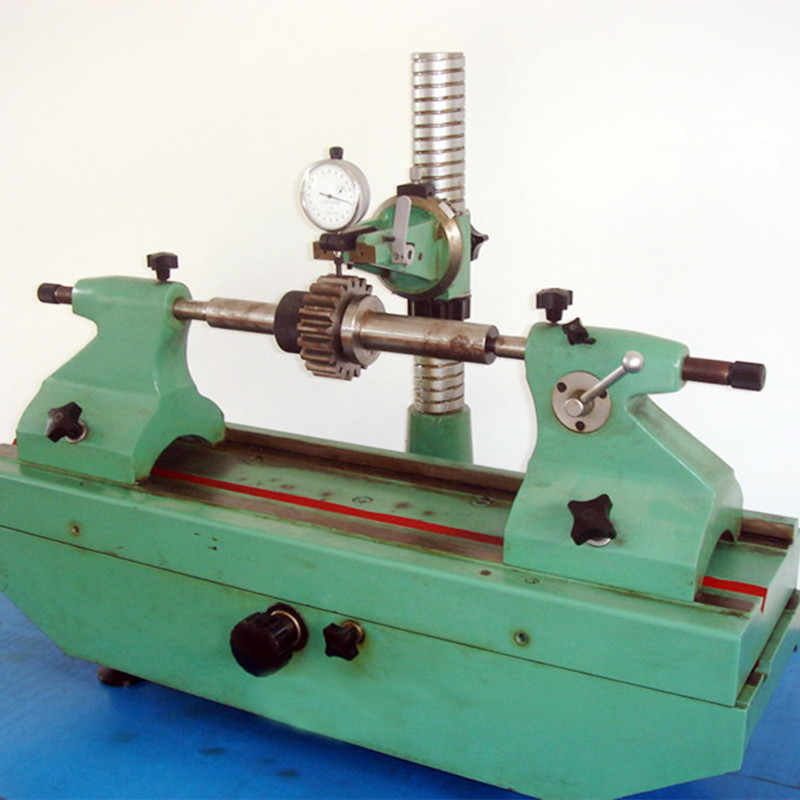

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.