Behind every reliable liquid transfer lies a silent guardian: the hose check valve. In a world of moving water, one backward trickle can ruin a system, contaminate a supply, or empty a pump’s prime. A hose check valve is the simple, trusted reply to that risk. It opens to let fluid flow in the desired direction, and it closes to prevent reverse flow the moment pressure shifts. The result is calmer operation, safer products, and longer life for your equipment.

What makes a hose check valve indispensable? It’s a one-way gate that protects pumps, tanks, and hoses from backflow. When pressure pushes forward, the valve opens; when pressure recedes, a spring or a delicate seat snaps the valve shut. That instant response stops contaminated water from siphoning back into clean lines, prevents chemical splashback in mixed-use systems, and keeps your prime steady so your pump doesn’t gulp air or lose efficiency. It’s a small component with a big impact on reliability and safety.

Hose check valves fit a wide range of settings—from backyard irrigation to industrial wash-downs, from agricultural sprayers to beverage lines. They are lightweight enough for quick field installation but rugged enough to withstand tough fluids, temperatures, and environments. Available in materials such as brass, stainless steel, and tough PVC, they offer compatibility with potable water, fertilizers, oils, and many cleaners. With various connection types—barbed, threaded, or compression—there’s a valve for almost any hose diameter and system layout. For environments demanding chemical resistance, select models with reinforced seals and corrosion-resistant bodies. For clean, quiet operation, choose designs that feature low-friction seats and reliable springs.

Choosing the right valve is about matching flow characteristics with your system’s needs: size, material, pressure range, and the nature of the liquid. Consider whether you need inline or compact inline options for tight spaces, and verify that the sealing material is compatible with your liquid to avoid swelling or degradation. Installation orientation matters too; most hose check valves perform best in a horizontal or slightly inclined position, with the flow direction clearly marked. Regular maintenance—quick checks for leaks, occasional seat cleaning, and timely replacement of worn parts—keeps the valve dependable year after year.

Investing in a high-quality hose check valve is investing in peace of mind. It guards your investments, reduces downtime, and helps you meet safety and quality standards with confidence. Choose a valve you can trust to move your operation forward—one that seals the deal every time the flow starts and every time it stops.

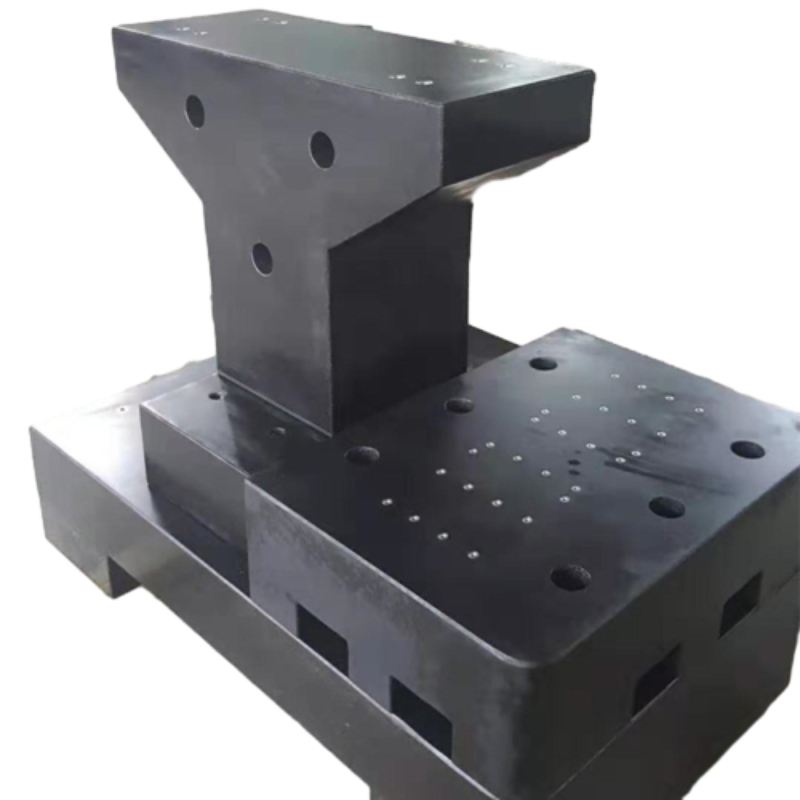

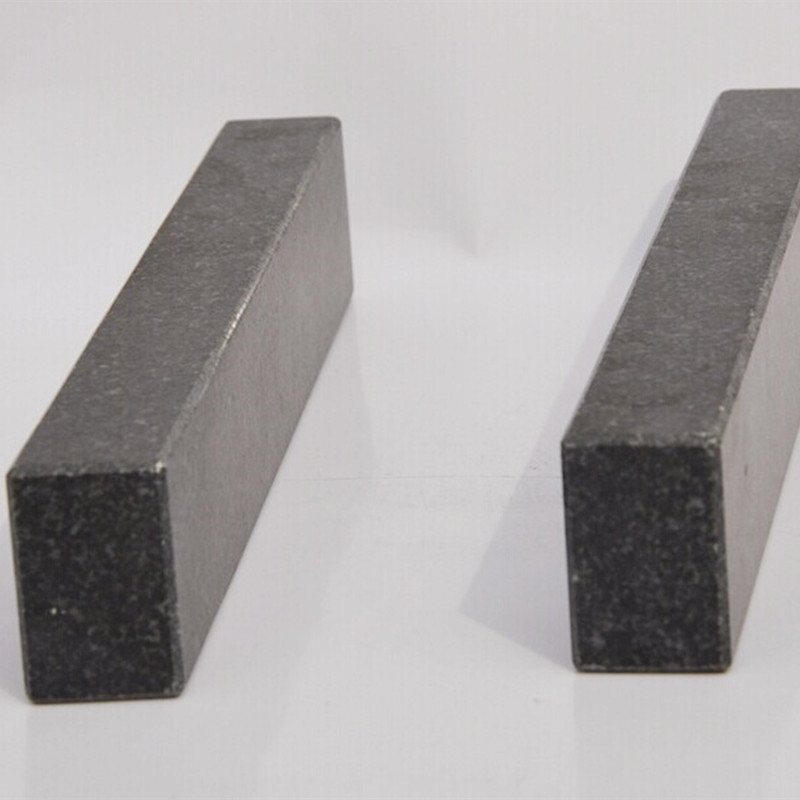

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.