In the quiet heartbeat of every fluid system, a tiny guardian stands between danger and efficiency: the non-return check valve. It is designed to let the flow move forward freely, then slam shut when the pressure reverses, sealing off backward flow. It sounds simple, but this one-way gate keeps our processes clean, safe, and reliable.

A non-return valve operates automatically, without any external control. Its purpose is to prevent backflow that could contaminate clean water, dilute a product, or reverse the flow that drives expensive pumps and sensors. By stopping reverse surges and siphons, it protects equipment, preserves product integrity, and reduces maintenance costs. In short, it is a frontline defender for process reliability and system longevity.

Across industries—from water treatment and food processing to chemical plants, oil and gas, and HVAC networks—the benefits are tangible. Backflow can cause cross-contamination, equipment damage, and costly downtime. A well-chosen non-return valve minimizes these risks, stabilizes pressure profiles, and enhances the overall efficiency of the plant. It is a small component with a big impact, quietly delivering peace of mind so operators can focus on performance, not emergencies.

When selecting a non-return valve, pay attention to a few core features:

- Valve type and size: swing, lift, or ball designs, with appropriate body material for the media.

- Materials and seals: stainless steel, bronze, or alloy bodies; seat materials and elastomer seals suited to temperature and chemical exposure.

- End connections and pressure ratings: flanged, wafer, or lug options; suitable PX ratings for the system.

- Cracking pressure and leakage: low cracking pressure for gentle systems; tight shut-off to prevent even minor backflow.

- Maintenance and accessibility: design for easy disassembly, inspection, and replacement of seats and seals.

Quality and reliability matter. Look for valves that meet recognized standards and have test data demonstrating leak-tight performance under representative conditions. A reputable supplier will offer engineering support, warranty coverage, and documentation such as material certificates and performance curves.

Whether you are upgrading an aging plant or designing a new one, a robust non-return valve is not just a component—it is a promise: flow in the right direction, safety strengthened, and operations safeguarded. Choose wisely, and let this quiet guardian do its job, day after day.

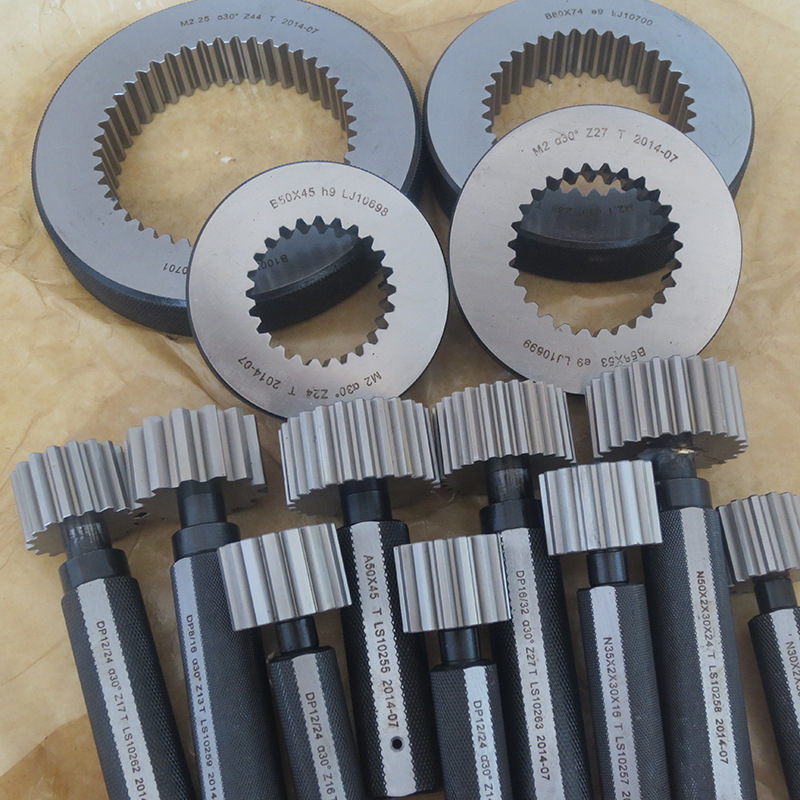

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.