Imagine a tiny gate that protects your water system from backflow, quietly doing its job so your faucets run clean and your appliances stay safe. That gate is a plumbing check valve. It is a one-way valve that allows water to move in the intended direction, but snaps shut the moment the flow reverses. In homes and factories alike, it’s the unsung hero against contamination, flood, and costly repairs.

Check valves come in several flavors, each tuned for different tasks. Swing check valves use a hinged flap that swings open with forward flow and seals shut when flow reverses. Tilting-disc and ball-check valves rely on a weighted disc to block reverse motion. Spring-loaded variants snap shut quickly, reducing the risk of backflow during sudden pressure changes. The right choice depends on your system’s pressure, velocity, and the space available for installation. Whether you’re outfitting a residential water line, an irrigation loop, a boiler, or a sump pump discharge, there’s a valve engineered to meet the demand.

Materials matter as much as design. Brass or bronze valves suit potable-water systems and high-temperature environments. Stainless steel delivers durability in tougher settings. For non-potable or specific chemical environments, CPVC or PVC models offer corrosion resistance and cost efficiency. Knowing your operating pressure and the size of the pipe helps you pick a valve with an appropriate pressure rating and flow characteristics, so you won’t compromise efficiency or safety.

The benefits are clear. A reliable check valve prevents backflow that could contaminate drinking water, damage equipment, or trigger costly shutdowns. It also guards against back-siphonage in appliances and irrigation systems, helping you preserve water quality and system longevity. In commercial or industrial settings, compliance with local plumbing codes and backflow prevention requirements is not optional—it’s a responsibility you can depend on.

Installation and maintenance are key to performance. Install in the indicated direction of flow, with clean connections and supported piping to avoid stress on the valve. Regular inspection for leaks, unusual noises, or sluggish closing is wise. If a valve leaks at the seat, doesn’t seal promptly, or shows signs of wear, replacement is usually the prudent choice. Periodic testing may be required by code or by your facility’s maintenance plan.

Choose a check valve you can trust—built for the task, backed by quality engineering, and supported by a provider who understands both residential comfort and industrial reliability. If you’re upgrading a system or designing a new one, talk to us about the right check valve solution for your flow, pressure, and safety needs. Your water—and your budget—will thank you.

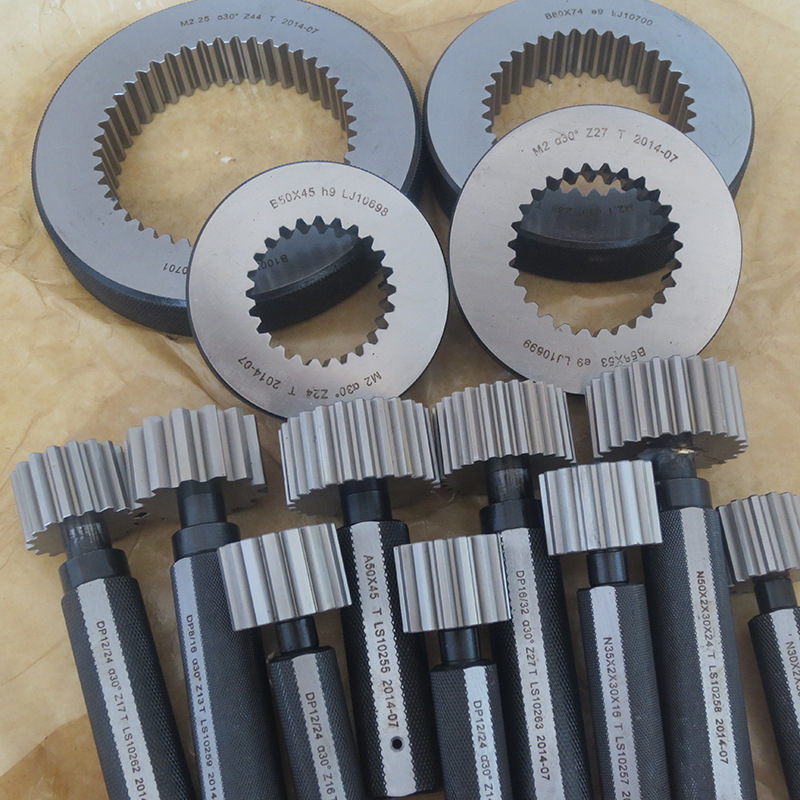

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.