Plug gauges are the unsung heroes of precision manufacturing. They don’t shout or sparkle, but a well-chosen gauge can tell you, in an instant, whether a hole will accept the part or reject it. In a world where tolerances shrink and reliability is non-negotiable, the humble plug gauge becomes your most loyal quality partner.

A go/no-go gauge works like a gatekeeper. The go gauge must slip through with minimal resistance, signaling that the bore is open enough to accept the part. The no-go gauge, by contrast, should not pass through; it defines the boundary where the fit becomes unacceptable. When used correctly, this simple test reveals whether every sequential component will assemble without grinding, force, or wasted time.

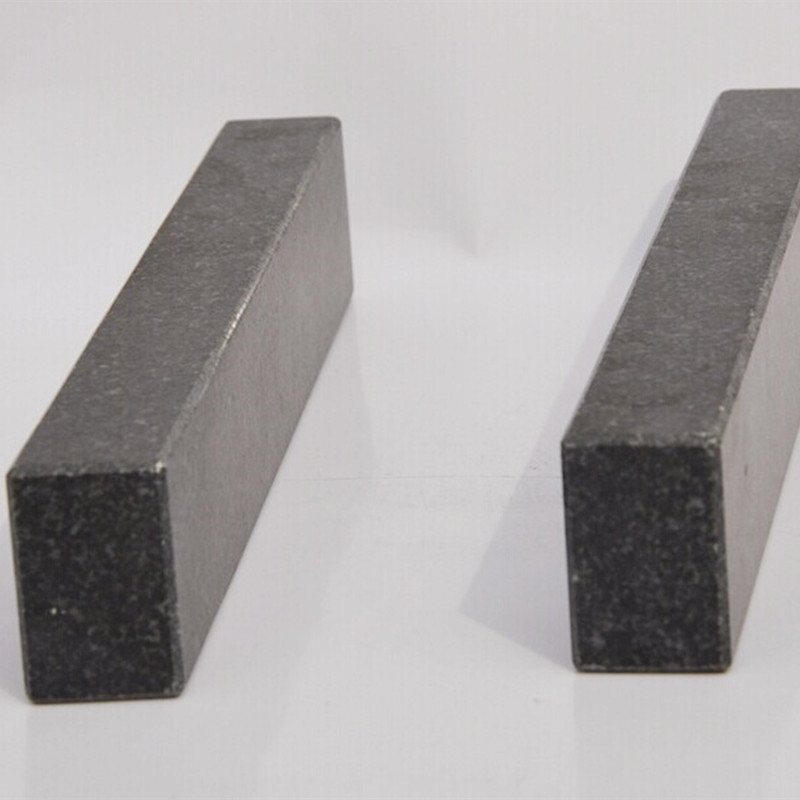

Quality construction matters. Solid plug gauges, typically steel or carbide, are mated to standardized tolerances and calibrated to traceable references. They offer long life in workshops where temperature, oil, and grime test the calm of even the best operators. Reversible designs and varied sizes ensure you can check everything from fastener holes to guide bores with confidence. In aerospace, medical devices, or automotive assembly, your gauges are not just tools—they are contracts you sign with your own process.

The right gauge program pays for itself. Fewer rejects mean less rework, less downtime, and faster throughput. Interchangeability becomes a guarantee, so an assembly line can run smoothly across shifts and sites. Calibration is not a ritual; it is a safeguard. Periodic calibration against traceable standards, proper handling, and clean storage preserve accuracy and reduce wear that could undermine your entire batch.

Choosing the right gauges means asking the right questions: Are you measuring internal diameters that require a precise go and no-go check? What range covers recurring work, and what size tolerances do you routinely meet? Do you need digital records or simple go/no-go checks for shop-floor speed? The best suppliers will listen, offer certified gauges, and stand behind their accuracy with service and support.

Invest in plug gauges they can trust—and your process will feel the difference in every finish, every fit, every time.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.