Taper ring gauge is used for ensuring accurate conical or tapered features on cylindrical parts. It is a precision instrument in the metrology toolkit, translating a design’s taper specification into a practical, repeatable test on the factory floor. When a customer demands a seal, a snug fit, or a smooth mating surface, the taper ring gauge provides a decisive answer: yes, that part is right; no, something needs adjusting.

A taper ring gauge consists of rings machined with a controlled inner bore that widens or narrows along its length, following a defined taper angle. Depending on the standard, the gauge may test external tapers on shafts, internal tapers on bores, or the cumulative length of the taper. The user slides the part through the gauge or places the gauge over the part. If the mating surfaces contact along the entire tapered length, the part passes; any gap, binding, or mis-match signals a deviation from the specification. This simple, direct feedback reduces guesswork and accelerates the early stages of production and the final inspection.

Taper ring gauges are essential in industries where precision seals and reliable leak-tight assemblies are non-negotiable. Automotive components such as turbine shafts, transmission sleeves, and crank pins rely on exact tapers to guarantee proper seating and concentricity. Hydraulic and pneumatic fittings demand consistent taper angles to ensure leak-free joints under pressure. In aerospace, even a tiny misalignment of a tapered interface can ripple through performance and safety. In manufacturing of measuring tools themselves, tunable tapers control how pieces mate, ensuring calibration chains stay intact.

Beyond mere tolerance checking, taper ring gauges support standardization and interchangeability. They provide a bridge between the engineer’s blueprint and the machinist’s setup, a ready-made reference for offset adjustments, tool wear monitoring, and process capability studies. Used alongside calipers, micrometers, and CMMs, they strengthen quality systems, traceability, and audit readiness. For buyers, reliable gauge sets translate into fewer returns, longer tool life, and a more predictable production rhythm.

To get the most from a taper ring gauge, keep it clean, calibrated, and stored in a controlled environment; choose the correct taper per the drawing (angle and length); and use consistent seating force and contact criteria during measurement. In short, a taper ring gauge is used for confirming conical precision, safeguarding performance, and speeding the journey from design to dependable product.

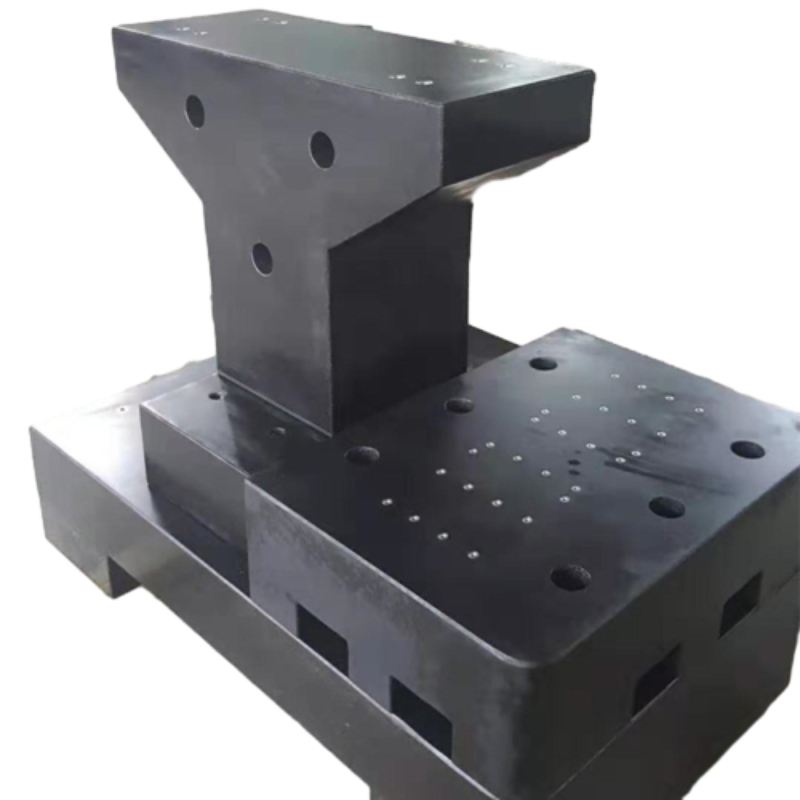

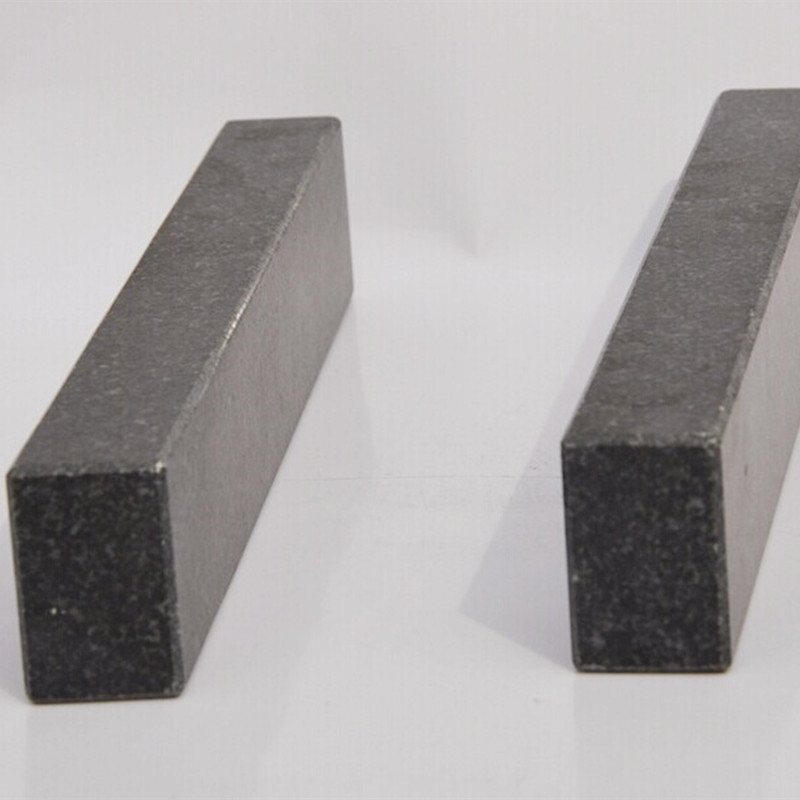

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.