Thread gauges are the unsung heroes of precision manufacturing. They ensure that a tiny thread, drawn to a hundredth of a millimeter, will thread cleanly into a mating part every single time. In a world where failure often hides in the smallest detail, a simple gauge keeps the bigger picture intact: performance, safety, and trust.

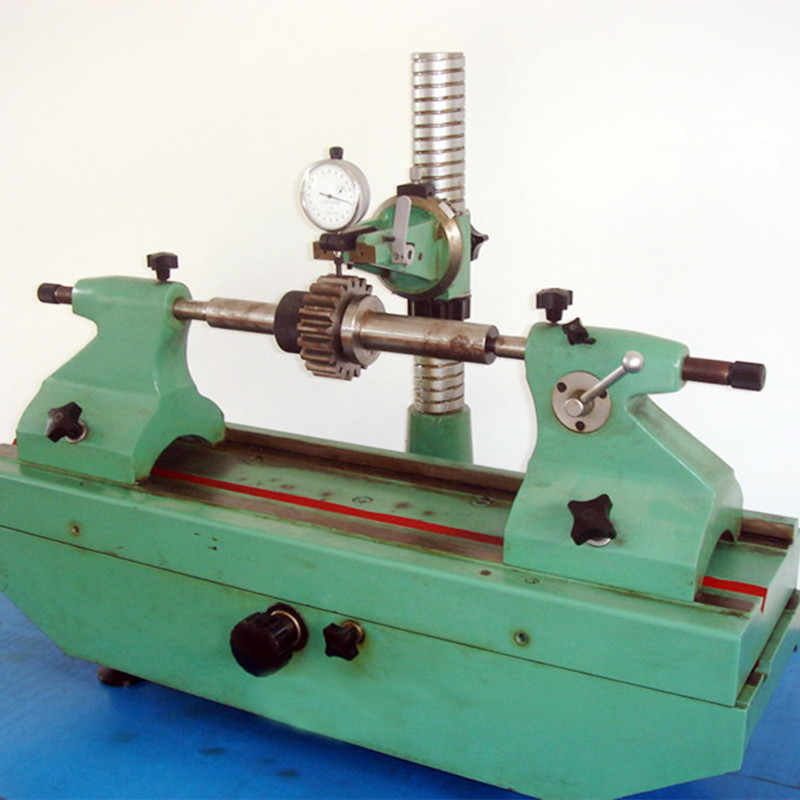

A thread gauge is not a single tool but a family. External threads are checked with ring gauges and go/no-go gauges; internal threads with plug gauges; the pitch—how tightly threads twist around the shaft—is verified with a pitch gauge. For the observer, the tool feels almost ceremonial: a slender disc or a slim blade, forged from hardened steel, waiting to smile or grimace when it meets its match.

Using a thread gauge begins long before the metal meets the machine. It starts with choosing the right standard: coarse or fine, metric or imperial, standard thread forms or specialized profiles. You lay the part on a clean bench, wipe away a speck of oil, and select the gauge size that should fit. With a careful touch, you slide the gauge over the threads or into the hole. A perfect light pass—“go” on a ring gauge, “no-go” on the counterpart—spurs a quiet confidence. If anything balks, you adjust, recut, or rework, never guessing and never wasting.

The payoff is immediate and tangible. In assembly lines, a correctly gauged thread becomes a promise kept: a bolt that threads with minimal torque, a nut that seats without crushing the joint. In maintenance, a missing spec is a sign of risk, and a thread gauge raises the alarm before it becomes a downtime expense. In design, it is a whisper from reality: the part you designed will marry the next, not just fit the drawing.

Today, a thread gauge is more than a tool—it is an ally for quality. Many sets offer interchangeable ring, plug, and pitch gauges, calibrated to international standards and traceable to laboratories. They’re robust enough for the shop floor, precise enough for the lab, and affordable enough to be a standard expectation rather than an exception.

Invest in a good thread gauge, and your productions, your repairs, and your reputation will thread together with smoother certainty. After all, greatness often lies in the threads that others never notice. Beyond the numbers, the use of thread gauge informs a culture. It teaches patience when the pitch refuses to mate and resilience when a batch must be reworked. It invites collaboration: machinists, designers, and inspectors speaking a shared language of tolerances. In a marketplace thirsty for reliability, a small tool that prevents misfit is a strategic choice, not a luxury. Choose gauges that endure, stay calibrated, and prove themselves every shift—because trust, once threaded, holds everything together.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.