In every pipeline, there is a quiet guardian—the flanged gate valve. It metal-bonds the promise of safety with the precision of engineering, delivering a seal that stands up to pressure, temperature, and time. When the flow stops, the gate slides into position with a deliberate, low-friction motion, and suddenly the system is isolated, predictable, and secure. This is the power of a well-made flanged gate valve: a robust connection at every joint, a steadfast shutoff when you need it most.

Designed for rugged reliability, a flanged gate valve combines a solid body, a sealing gate, and a carefully engineered seating surface to deliver leak-tight performance. The flanged ends create a durable, bolt-down mating with piping, ensuring proper alignment and easy replacement in demanding environments—from refineries and power plants to water treatment and chemical processing. The valve is suited for high-pressure, high-temperature service where a long, predictable life matters as much as a precise shutoff. Depending on the design, you can opt for metal-to-metal seats for demanding conditions or soft seats for tight shutoffs at moderate temperatures, giving you the right balance of resilience and efficiency.

Operation is simple yet sophisticated. The handwheel or actuator translates rotational input into linear motion, lifting a wedge or disk clear of the seat. When fully opened, the gate retreats, allowing an unobstructed, full-bore flow. When closed, the seating surfaces meet to form a tight barrier, dramatically reducing leakage. Packing and stems are engineered to resist leaks around the stem, even as cycles accumulate. In the long run, this translates to lower maintenance needs and fewer unplanned shutdowns.

Choosing a flanged gate valve means investing in versatility. It handles isolation tasks across a broad range of fluids—clean water, slurries, oils, and aggressive chemicals—while offering reliable performance and straightforward maintenance. The flange-to-flange interface also simplifies installation, inspection, and future retrofit, reducing total life-cycle costs. With proper material selection and coating, these valves resist corrosion and wear, extending service life in challenging settings.

Our flanged gate valves are manufactured to rigorous standards, backed by traceable materials, comprehensive testing, and responsive after-sales support. We tailor selections to your system’s specifics—pressure class, temperature range, fluid compatibility, and fit-for-purpose seating. Whether you’re modernizing a facility or planning a greenfield project, our valves bring peace of mind: durable, dependable shutoff that keeps your operations flowing smoothly.

Choose a flanged gate valve not just as a purchase, but as a promise—of safety, efficiency, and enduring performance in every turn of the wheel.

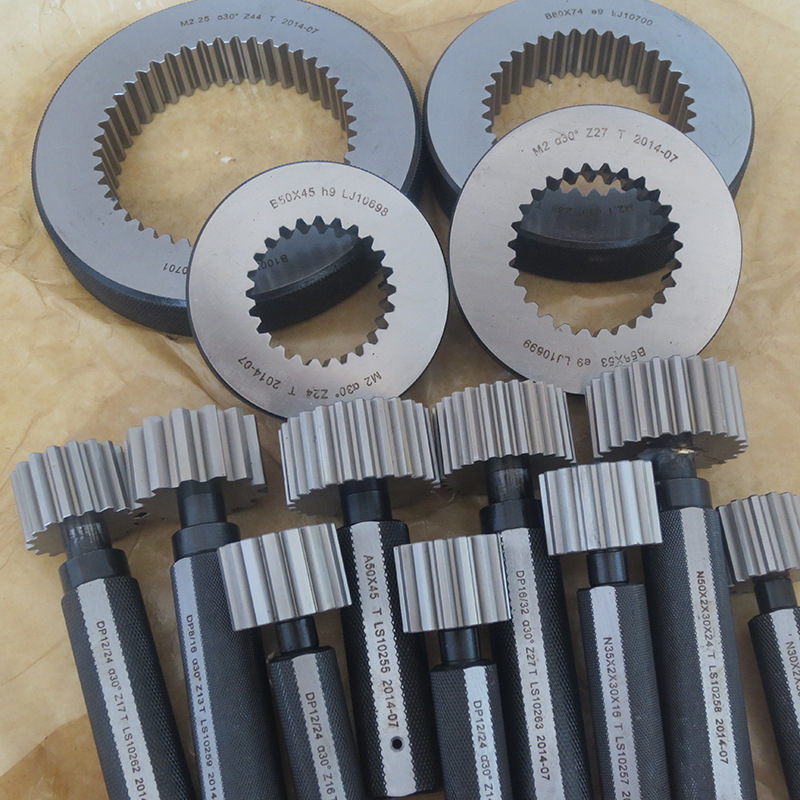

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.