In every factory, the hum of machines tells a tale of efficiency and progress—until it doesn’t. Vibrations travel through floors, mounts, and foundations, whispering fatigue into bearings, misalignment into measurements, and noise into fatigue for the people nearby. That is where machine vibration pads step in, quietly doing their job: isolating, damping, and preserving the integrity of your equipment and your operation. They are small components with a big impact, turning rough conditions into smoother performance.

Machine vibration pads are engineered to absorb energy at the source. Made from robust damping materials—such as engineered rubbers, viscoelastic compounds, or multi-layer composites—they compress and rebound with precision, reducing transmission to the supporting surface. The result is less vibration at the machine base, lower peak forces in the floor, and less stress on fasteners and foundations. They also shield floors and surrounding structures from unwanted vibration, cutting maintenance costs and the risk of structural damage over time.

The benefits go beyond mechanics. When vibrations are controlled, machines stay closer to their ideal operating conditions. Dimensional stability improves, leading to tighter tolerances and better product quality. Noise levels drop, creating a more comfortable, safer workplace and meeting regulatory or client expectations for quieter environments. Operators experience less fatigue, and preventative maintenance intervals can be extended because components wear more slowly under steady loads. In short, vibration isolation pads help you do more with less: more uptime, more precision, more peace of mind.

These pads come in a range of sizes, loads, and materials tailored to different applications. Whether you’re equipping CNC machines, chillers, pumps, compressors, or heavy presses, there’s a pad designed to match the static load, dynamic stiffness, and environmental conditions. Customization is common: thickness, hardness, temperature range, and resistance to oils or chemicals can all be chosen to fit your exact setup. Easy installation and reliable performance mean your upgrade can be quick and non-disruptive, turning a simple retrofit into a long-term asset.

Choosing the right machine vibration pads is a smart, proactive decision. Start with the load and vibration profile, then consider temperature, chemical exposure, and the desired level of isolation. If you’re uncertain, consult a vibration-control specialist or request a recommended spec sheet. With the right pads in place, your machines run smoother, your floors stay intact, and your team performs at its best. Reach out today to learn how vibration isolation can protect your assets and elevate your production line.

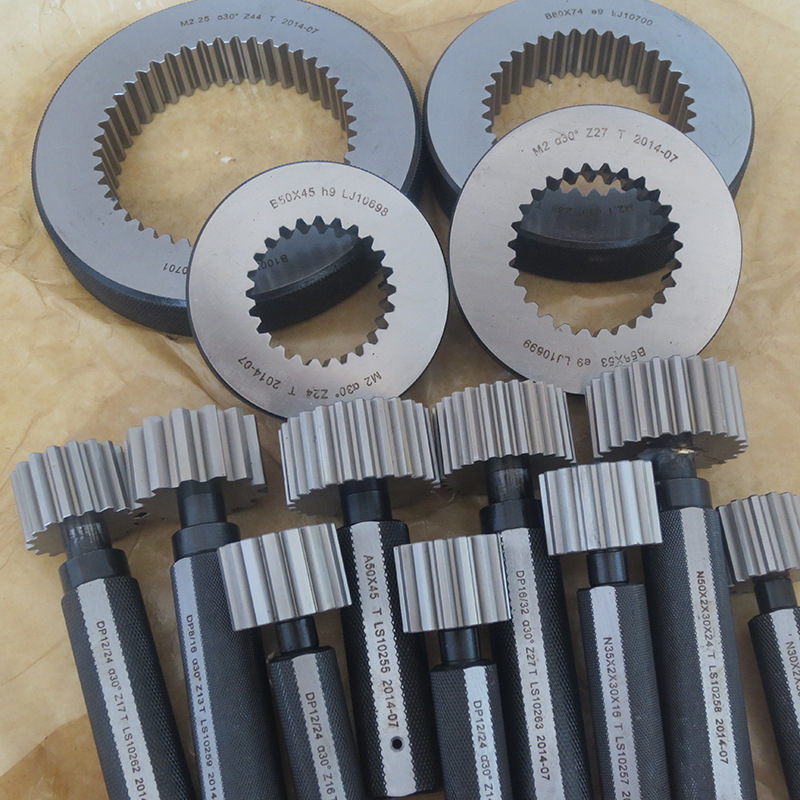

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.