Quality begins with a single, reliable measurement. In machining and assembly, thread plug gauges are the quiet workhorses that ensure every internal thread accepts a fastener with the right fit. They are simple in concept—a plug that can thread into a hole to confirm the thread’s size and tolerance—but sophisticated in practice. When Go and No-Go gauges are used correctly, they turn guesswork into guaranteed quality, helping you reduce rework, speed up production, and protect your brand’s reputation.

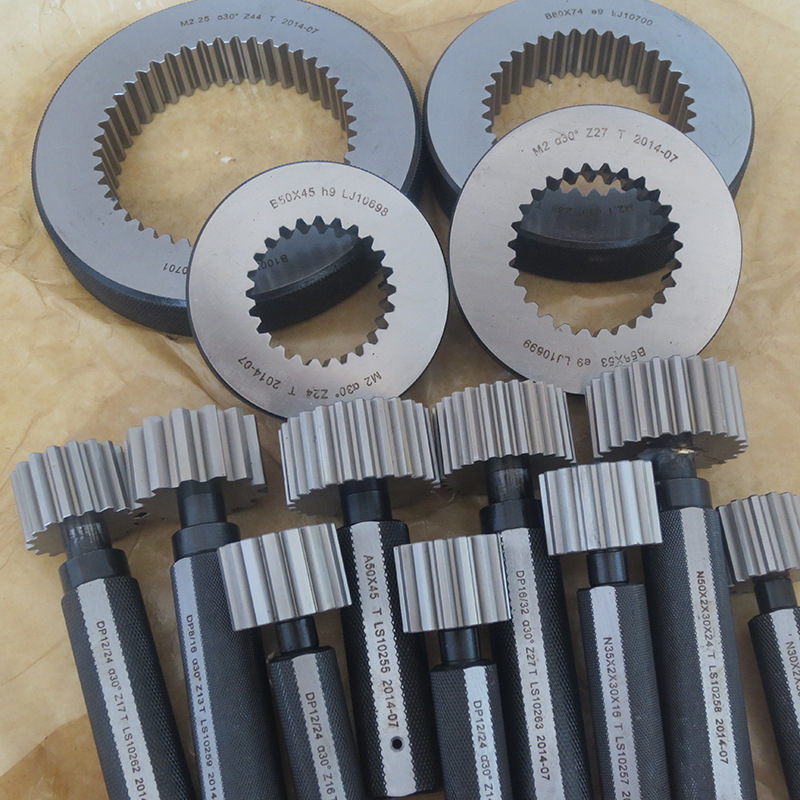

Here are the main types you’ll encounter:

-

Straight thread Go/No-Go plug gauges: The standard workhorse for most straight threads (metric and inch). The Go end should thread in to the specified depth, while the No-Go end must not pass beyond the limit. Used in pairs, they verify both the lower and upper bounds of a thread feature.

-

Two-step plug gauges: One instrument with two steps, letting you check both limit sizes in a single tool. This design saves time on high-volume lines and keeps your gauging consistent across shifts.

-

Tapered thread plug gauges: Essential for pipe and tapered-thread applications (NPT, BSPT, and friends). They reproduce the gradual engagement of a tapered thread, ensuring the right seal and fit along the entire length.

-

Special/custom thread plug gauges: For uncommon forms (ACME, buttress, left-handed threads, or non-standard profiles), manufacturers can craft gauges that mirror the exact thread geometry. These keep critical applications precise where off-the-shelf options won’t.

-

Material and finish variations: Gauges come in hardened steel, carbide-tipped, or stainless steel, with finishes that resist wear in rugged shop environments. The choice affects longevity in production lines with repeated use and exposure to lubricants and chips.

Why these types matter to you

- Accuracy and speed: Go/No-Go concepts empower fast, repeatable checks that catch mistakes at the source, reducing downstream scrap.

- Consistency across batches: Well-matched gauges establish a stable reference across machines and operators.

- Calibration and traceability: Reputable gauges carry standards-based calibration, preserving measurement integrity over time.

How to choose

- Identify the thread standard (metric vs inch, pitch, and tolerance class) and whether you’re dealing with straight or tapered forms.

- Decide on the right combination: most days, a Go/No-Go pair suffices; for high-output lines, a two-step gauge can streamline checks.

- Consider material and wear resistance, especially for high-volume shops, and ensure a clear calibration/traceability plan.

In short, mastering the types of thread plug gauges equips your team to deliver flawless assemblies, faster throughput, and unwavering quality. Invest in purpose-built gauges, and you’ll turn every thread into a promise kept.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.