Behind every flawless weld is a dependable foundation. For fabricators, a welding table is more than a workspace—it is the stage on which precision, speed, and safety perform. A welding table manufacturer that truly understands this can transform a shop from good to great, unlocking new levels of repeatability, efficiency, and pride in your craft.

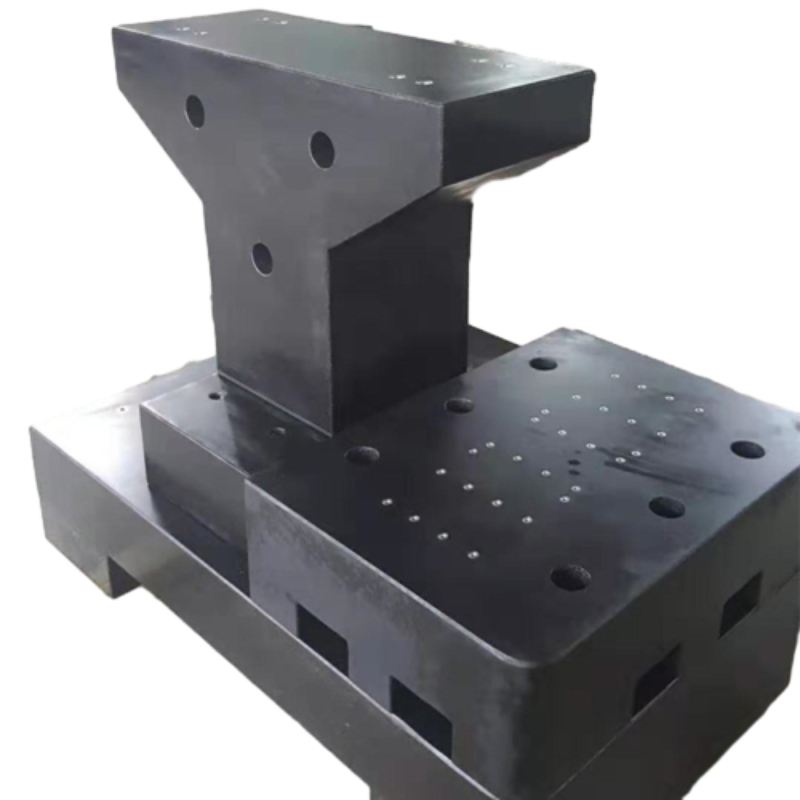

What makes a table stand out? First, rigidity and flatness. The top must hold fast under heat, vibration, and the pressure of clamps, without warping. Our tables are engineered with a robust steel core, precisely milled to stay flat under demanding workloads. The surface is corrosion resistant, easy to clean, and designed to withstand the rigors of daily welding, grinding, and tamping. A well-designed table keeps you in alignment, reduces rework, and protects tools and parts.

Second, flexibility is the lifeblood of a busy shop. Look for modular elements: removable panels, indexed T-slots, dog holes, and a wide ecosystem of clamps, stops, and vices that snap into position without screws hunting for a new home. A good welding table manufacturer offers a modular system that grows with your business—starting with a sturdy base frame and expanding into large, multi-station workstations. Quick-change accessories mean you can reconfigure in minutes, not hours, turning any job into a precise, repeatable process.

Third, precision manufacturing and quality control. Every table should arrive square, level, and ready to use. This means meticulous machining, strict dimensional tolerances, and rigorous testing. A trusted supplier provides documentation, certifications, and ongoing support—so you’re never left guessing whether your setup will hold its promise next week or next year.

Fourth, service and partnership. The right manufacturer doesn’t just sell you a table; they safeguard your investment with spare parts availability, proactive maintenance guidance, and responsive technical support. Transparent lead times, clear pricing, and a willingness to tailor dimensions, hole patterns, and accessories to your workflow make a real difference in a fast-paced fabrication environment.

Choosing the right welding table manufacturer is choosing a collaborator in your craft. It’s about more than a product—it’s about predictable accuracy, safer operations, and a shop that can scale with your ambitions. If you’re ready to elevate every weld, connect with a partner who designs strength, supports your process, and helps your team perform at its best. Your future projects deserve nothing less.

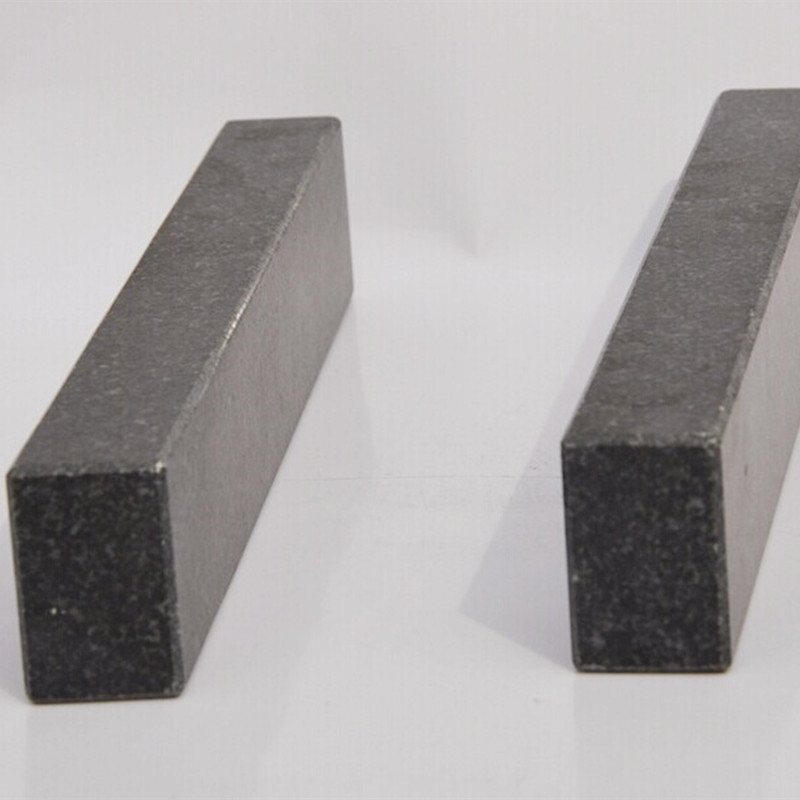

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.